Details Images

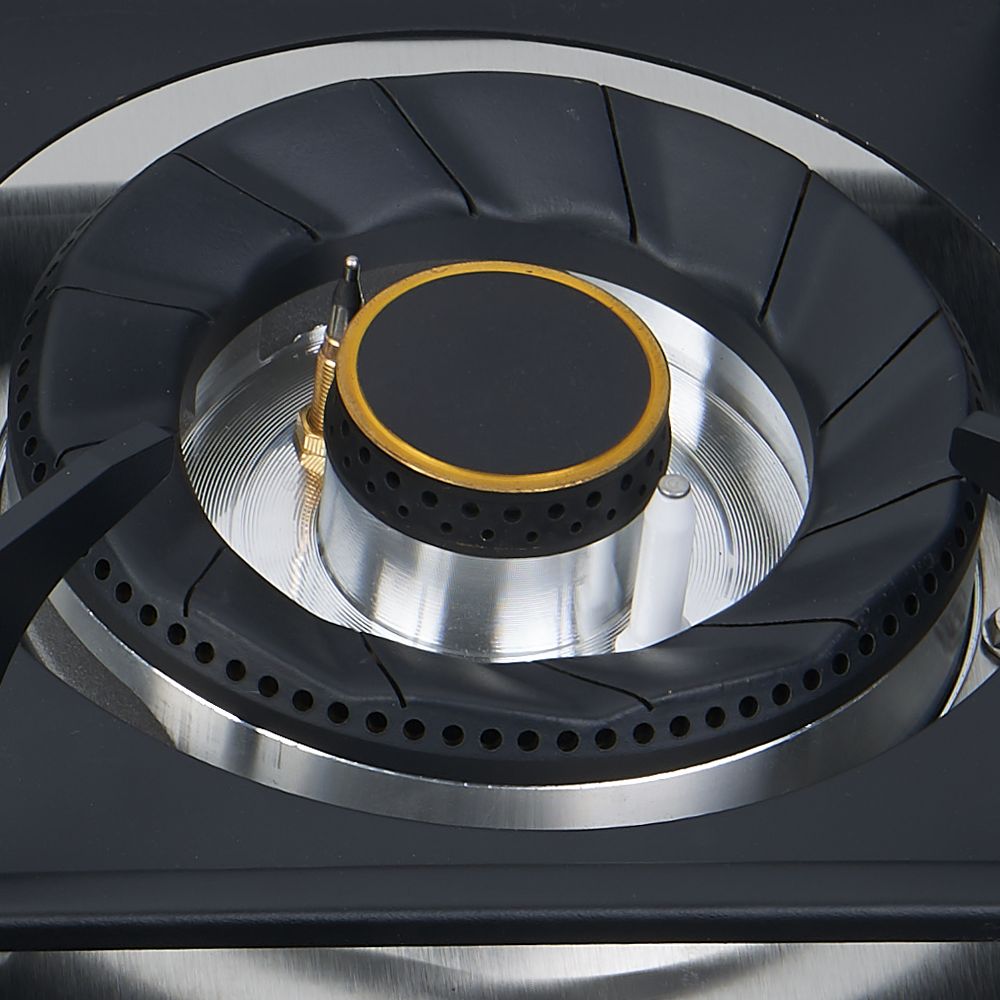

120MM brass burner cap. 4.2Kw

Square Cast Iron with fire board Pan Support

Metal knob

| NO | PARTS | DESCRIPTION |

| 1 | Panel: | 7mm Tempered Galss, customised logo is available on the glass. |

| 2 | Panel Size: | 750*430MM |

| 3 | Bottom Body: | Galvanized |

| 4 | Left and Right Burner: | 120MM brass burner cap. 4.2Kw |

| 5 | Middle Burner | Chinese SABAF Burner 3# 75MM. 1.75Kw. |

| 6 | Pan Support: | Square Cast Iron with fire board. |

| 7 | Water Tray: | Square SS |

| 8 | Ignition: | Battery 1 x 1.5V DC |

| 9 | Gas Pipe: | Aluminum Gas pipe, Rotary connector. |

| 10 | Knob: | Metal |

| 11 | Packing: | Brown box, with left+right+upper foam protection. |

| 12 | Gas Type: | LPG or NG. |

| 13 | Product Size: | 750*430MM |

| 14 | Carton Size: | 800*480*200MM |

| 15 | Cutout Size: | 650*350MM |

| 16 | Loading QTY: | 430PCS/20GP, 1020PCS/40HQ |

Model Selling Points?

1 As the stove with iron fire cover has rusted over a long period of time, the rust spots have blocked the vent hole of the fire cover for a long time, causing the flame to not burn out.

Solution: Clean the fire cover frequently. When cleaning the cooker, do not just wipe the panel. Deal with the dregs and rust spots in the flame distributor frequently.

2 The opening size of the cabinet top is larger than that of the cooker. Because it is too large, the place where the cooker is stressed is not the metal shell, but the glass panel. The long-term hanging force is easy to make the cooker panel burst.

Solution: Be sure to determine the size of the cooker first, and then open the hole of the cabinet. The hole will be as large as the cooker.

3. The user puts the hot things directly on the panel, such as the used frying pan, the boiled kettle, etc.

Solution: Remind the user to avoid putting hot things on the glass panel immediately.

4. Gas leaks from the cooker joint, gas pipe or other parts, and the leaked gas burns to make the cooker locally high temperature and cause explosion.

Solution: regularly check the gas valve, regularly check the gas interface, regularly replace the pressure reducing valve of liquefied gas, and select the corrugated pipe with steel wire when installing.

5 The placement of the flame splitter, also known as the fire cover, after cleaning is not consistent with the bottom, which causes the flame splitter to backfire for a long time or flame out from the gap. This will not only cause the panel to burst, but also easily deform the flame distributor.

Solution: After cleaning the fire cover, it must be put back as it is, and there should be no gap between the fire cover and the seat.